Gabions Products

- Military Gabions

- Hot Dipped Galvanized Gabion Mesh Cells

- Welded Mesh Gabions Architectural Wall Cladding

- Gabions (Gabiony)

- Galfan + PVC Coated Gabions

- Gabion Mattresses for Flood Protection Embankment

- Planted Gabion Walls

- Gabions and Geotextiles for Bridge Construction

- Gabion Basket Hot Dip Galvanized

- Gabions P. V. C. Coated Galvanised Wire Box

- Gabions River Training Works

- Geotextile Fabric

- Woven Wire Mesh Cages for Gabion Project

- Gabion Fence

- Welded Gabions Coating Galfan

- Gabion Baskets Double Twisted Galvanized

- Triple Twisted Wire Mesh Gabions

- Gabion Box

- Woven Gabions

- Gabion Baskets

- Wire Mesh Gabion Mattress

- Gabion Cages (Stone Box)

- Gabion Wall

- Hexagonal Gabions Netting

- Gabions Machine

- Welded Gabions

- Sack Gabions

- Reinforced Gabions

- Gabion faced reinforced soil walls

- Gabion Mattress

- Gabions for Water Conservancy

- Gabions for Bridge Protection System

- Gabion Wall Drop Structures

- Modular Gabions as Architectural Elements

- Gravity Wall of Gabions

- Gabions for Headwalls or Wingwalls

- Channel Linings

- Modular Gabions for Rockfall Netting System

Gabion Basket, Cage and Mesh Roll Hot Dipped Galvanized

Hot Dipped Galvanized Gabion basket, cage and mesh rolls are manufactured and supplied in ASTM standard for USA and other countries.

Gabion baskets, cages and mesh rolls are hot dip galvanised according to ASTM A975 Class 3 with a thick zinc coating corrosion protection of minimum 260 g/m², suitable for soil reinforcement, retaining walls, riverbank stabilization, rockfall protection and landscaping projects.

Gabion baskets made of steel wire hot-dipped zinc galvanized are available in dimensions 1x1x1 m, 2x1x1 m, and 3x1x1 m. Wire diameter ranges from 2.0 mm to 5.0 mm, mesh sizes 50x50 mm, 60x80 mm, and 80x100 mm.

Gabion cage made of steel wire hot-dipped zinc galvanized are in dimensions 2x1x1 m, 2x1x0.5 m, and 3x1x1 m. Wire diameter 3.0 mm to 5.0 mm, mesh sizes 60x80 mm and 80x100 mm.Gabion mesh rolls made of steel wire hot-dipped zinc galvanized are supplied in rolls in width 1m to 2m, length 25m to 30m. Wire diameter typically ranges from 2.0 mm to 4.0 mm, mesh sizes 50x50 mm, 75x75 mm, and 100x100 mm.

Hot Dipped Galvanized Gabions are delivered in following forms:

Gabions with all components mechanically connected are supplied in the collapsed form, the gabion basket and cages are folded or bundled, gabion meshes are rolled, for shipping. Bundles are banded together at the factory for ease of shipping and handling.

All gabions products are labeled in bundles with the dimensions of the gabions, the number of pieces and the color code per customers specific requirements.

GABIONS HOT DIPPED GALVANIZED PRODUCTS - BASKETS, CAGES, MESH ROLLS

GABION BASKET, HOT-DIP.GALVANIZED STEEL WIRE

WOVEN TYPE

SIZE: 2 mtr x 1 mtr x 1 mtr

Wire Dia: 4 mm

Mesh Size : 76.2 x 76.2 mm

Accessories : spiral wire

GABION CAGE , HOT-DIP GALVANIZED STEEL WIRE

DOUBLE TWISTED GABION BOX

SIZE: 1 mtr x 1 mtr x 0.5 mtr

Wire Dia: 4 mm

Mesh Size : 60*80 mm

GABION MESH ROLL, HOT-DIP GALVANIZED STEEL WIRE

Wire diameter: 2.7 mm

Mesh Size: 60*80 mm

Size: 2 mtr x 50 mtr Roll

GABION MESH ROLL,HOT-DIP GALVANIZED STEEL WIRE

Wire diameter: 3.0 mm

Mesh Size: 80*100 mm or 100*120 mm

Size: 1 mtr x 50 mtr Roll

Lacing wire – 2.2 mm dia , HOT DIP GALVANIZED STEEL WIRE

WIRE MESH GABIONS QUALITY - in

compliance with ASTM A975 for double twisted wire mesh gabions

Supplied with geotextile and filter fabrics, help with assembling, filling and tying open wire mesh rectangular gabions, baskets and cages.

Gabions are manufactured in variable sizes, uniformly partitioned into internal cells, interconnected with other similar units, and filled with stone at the project site to form flexible, permeable, monolithic structures. Gabions are manufactured with all components mechanically connected with the exception of the mattress lid, which is produced separately from the base.

All gabions wire materials are in compliance with ASTM A975 for double twisted wire mesh gabions.

REFERENCES

AMERICAN ASSOCIATION OF STATE HIGHWAY AND TRANSPORTATION OFFICIALS (AASHTO)

| AASHTO M 288 | (2017) Standard Specification for Geosynthetic Specification for Highway Applications |

ASTM INTERNATIONAL (ASTM)

| ASTM A313 | (2017) Standard Specification for Stainless Steel Spring Wire |

| ASTM A370 | (2017a) Standard Test Methods and Definitions for Mechanical Testing of Steel Products |

| ASTM A641 | (2009a; R 2014) Standard Specification for Zinc-Coated (Galvanized) Carbon Steel Wire |

| ASTM A764 | (2007; R 2017) Standard Specification for Metallic Coated Carbon Steel Wire, Coated at Size and Drawn to Size for Mechanical Springs |

| ASTM A975 | (2011; R 2016) Standard Specification for Double-Twisted Hexagonal Mesh Gabions and Revet Mattresses (Metallic-Coated Steel Wire or Metallic-Coated Steel Wire With Poly(Vinyl Chloride) (PVC) Coating) |

| ASTM B117 | (2016) Standard Practice for Operating Salt Spray (Fog) Apparatus |

| ASTM C136 | (2014) Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates |

| ASTM C33 | (2016) Standard Specification for Concrete Aggregates |

| ASTM D5312 | (2012; R 2013) Evaluation of Durability of Rock for Erosion Control Under Freezing and Thawing Conditions |

| ASTM D5519 | (2015) Particle Size Analysis of Natural and Man-Made Riprap Materials |

PRODUCTS MATERIALS

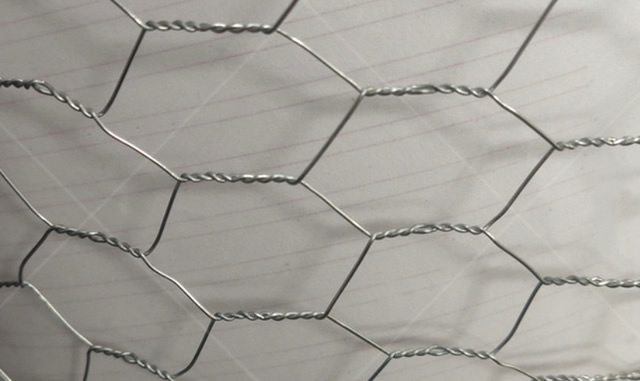

Double twisted wire mesh Gabions

Double twisted wire mesh gabions are manufactured with a non-raveling mesh made by twisting continuous pairs of wires through three half turns (also known as double twisted) to form a hexagonal-shaped opening. Gabion sizes, wire diameters, mesh opening sizes, and tolerances shall comply with the requirements of ASTM A975:

| Characteristics | Dimensions and Wire Diameters |

| Mesh Type | 8 by 10 |

| Mesh Opening | 3.25 inches by 4.5 inches |

| Mesh Wire | 0.120 inch |

| Selvedge Wire | 0.150 inch |

| Lacing Wire | 0.087 inch |

| Fasteners | 0.118 inch |

| Stiffeners: | |

| Using Lacing Wire | 0.087 inch |

| Preformed | 0.150 inch |

| *All dimensions and wire diameters are minimum nominal values | |

Gabions Hot Dip Zinc Coating shall meet the following test requirements:

(1) Metallic Coating: The coating weights shall conform to the requirements of ASTM A641, Class 3 (Style 1).

(2) Wire Tensile Strength: The tensile strength of the wire used for the double twisted mesh, lacing wire, and stiffener, when tested in accordance with Test Methods and definitions ASTM A370, shall be in accordance with the requirements of ASTM A641 (Style 1)

(3) Mesh Strength and Panel to Panel Joint Strength: The minimum strength requirements of the mesh, selvedge wire to mesh connection, panel to panel connection, and punch test, when tested in accordance with ASTM A975 Section 13.1. The strength values reported in lb/ft are referred to the unitary width of the specimen. The panel to panel test shall demonstrate the ability of the fastening system to achieve the required strength, and indicate the number of wire revolutions for the lacing wire or the ring spacing for ring fasteners used. The same number of wire revolutions or ring spacing shall be used in the field installation. Pleating the based panel to obtain internal panels is prohibited.

| (Minimum Strength Requirements of Mesh and Connections) | |

| Test Description | Gabions, metallic coated |

| Tensile strength parallel to twist | 3500 lb/ft |

| Tensile strength perpendicular to twist | 1800 lb/ft |

| Connection to selvedges | 1400 lb/ft |

| Panel to panel (using lacing wire or ring fasteners) | 1400 lb/ft |

| Punch Test | 6000 lb |

Wire Fasteners for Gabions

Fastening systems are recommended for woven wire gabions, according to ASTM A975, are steel ring fasteners for metallic coated gabions. For each shipment of wire gabions delivered, duplicate test reports or records are provided, for having been performed during the last year on all material contained within the shipment meets the composition, physical, and manufacturing requirements stated in this specification.

Ring fasteners for woven wire gabions:

Test results

meet the

requirements of the specifications, according to the following criteria:

- (1) That the fastener system can consistently produce a panel to panel joint strength as indicated for double twisted wire mesh gabions;

- (2) That the fastener system does not cause damage to the protective coating on the wire.

Samples of wire fasteners with certified test records shall be submitted at least 60 days in advance for approval.