Gabions Products

- Military Gabions

- Hot Dipped Galvanized Gabion Mesh Cells

- Welded Mesh Gabions Architectural Wall Cladding

- Gabions (Gabiony)

- Galfan + PVC Coated Gabions

- Gabion Mattresses for Flood Protection Embankment

- Planted Gabion Walls

- Gabions and Geotextiles for Bridge Construction

- Gabion Basket Hot Dip Galvanized

- Gabions P. V. C. Coated Galvanised Wire Box

- Gabions River Training Works

- Geotextile Fabric

- Woven Wire Mesh Cages for Gabion Project

- Gabion Fence

- Welded Gabions Coating Galfan

- Gabion Baskets Double Twisted Galvanized

- Triple Twisted Wire Mesh Gabions

- Gabion Box

- Woven Gabions

- Gabion Baskets

- Wire Mesh Gabion Mattress

- Gabion Cages (Stone Box)

- Gabion Wall

- Hexagonal Gabions Netting

- Gabions Machine

- Welded Gabions

- Sack Gabions

- Reinforced Gabions

- Gabion faced reinforced soil walls

- Gabion Mattress

- Gabions for Water Conservancy

- Gabions for Bridge Protection System

- Gabion Wall Drop Structures

- Modular Gabions as Architectural Elements

- Gravity Wall of Gabions

- Gabions for Headwalls or Wingwalls

- Channel Linings

- Modular Gabions for Rockfall Netting System

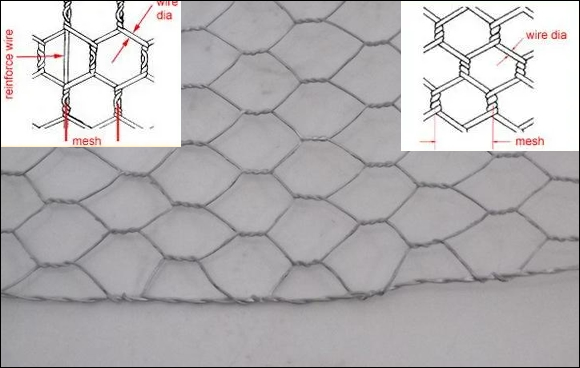

Hexagonal Wire Netting- Twisted Woven Gabion Wire Mesh-Double Twisted, Triple Twisted-Fabrication Wire Mesh to Gabions

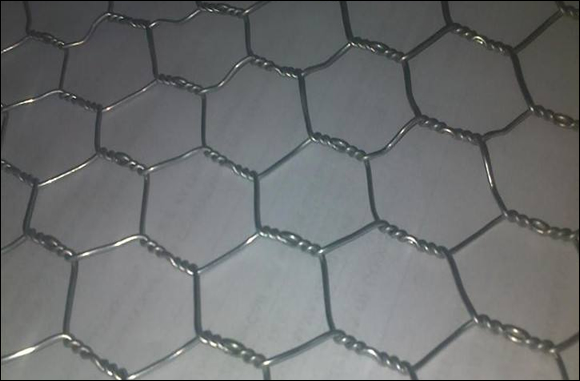

Hexagonal Wire Netting is a kind of twisted woven wire mesh product characterized by hexagonal-shaped openings. It is commonly used for gabions, chicken wire fencing, insulation, construction reinforcement and gardening.

Structure and Features: Hexagonal wire mesh is also called twisted wire mesh, due to the weaving method of the wires intertwined to form the mesh. This twisting process enhances strength and durability of the mesh fabric, making it suitable for various applications such as gabion work, fencing, poultry enclosures, and reinforcement in construction.

Wire Diameter: The diameter of the metal wires used vary according to the size of the hexagon opening.

For galvanized hexagonal wire, metal wire with a diameter of 0.3mm to 2.0mm is commonly used. Twisted woven hexagonal mesh with PVC-coated wire, diameter of PVC wire with an outer coating ranges from 0.8mm to 2.6mm. Twisted into a hexagonal shape, the line on the edge of the outer frame can be made into single twisted,double twisted,triple twisted and movable edge wires.

Why Hexagonal Wire Netting used for Gabion Mesh?

Hexagonal twisted wire mesh is ideal for gabions due to flexibility, strength, corrosion resistance, effective erosion control, lightweight structure and ease of installation.

Hexagonal double twisted gabion mesh is commonly used for retaining walls, erosion control and other construction applications.

How is Hexagonal Mesh Fabricated into Gabions?

Hexagonal wire mesh is fabricated into gabion baskets, boxes mattresses, through the following steps:

-

Cutting: Wwire mesh is cut to size based on the dimensions of the gabion basket being constructed.

-

Bending and Forming: The cut wire mesh panels are then bent and formed into basket shape, typically a rectangular box, or cage container. Bending the mesh fabric along the edges to create the sides, bottom, and top of the basket.

-

Assembly: Mesh panels are assembled together by securing the edges using lacing wire, C-rings, or other fastening methods. The edges are tightly joined to ensure the structural integrity of the basket.

-

Reinforcement: Vertical and horizontal stiffeners or diaphragms are added inside the basket. These reinforcements help the gabion maintain its shape and provide additional support when filled with stones.

Twisting Styles:

Twisting method of the wire can affects the durability and strength of the gabion mesh. Three twisting methods are used in the manufacture of hexagonal gabion mesh:

-

Single Twist: Twisting each wire once around the adjacent wire. Single twisted hexagonal gabion mesh offers a simple but less strong connection, not popularly used.

-

Double Twist: Twisting each wire twice around the adjacent wires. Double twisted hexgonal gabion mesh offers increased strength and durability, this is most common method for gabion mesh.

-

Triple Twist: Twisting each wire three times around adjacent wires. Triple twisted gabion mesh offers highest strength and resistance to unravelling for maximum durability. Costs higher compared with double twisted mesh, yet stronger.

Double and triple twist wire mesh are preferred for most gabion works due to superior strength and stability.

Weaving: Three types for hexagonal wire mesh according to twist directions: Straight twisted, reverse twisted, straight & reverse twisted, single or double edge.

Wire Material:

Hexagonal wire netting is made of twisting carbon steel wire, electro or hot dipped galvanized wire, plastic coated wire.

Application:

Hexagonal wire netting can be fabricated into gabion boxes and mattress for flood control. Once the stones are placed inside, the gabion boxes can be laid to form walls or banks that protect against water and flooding. Hexagonal wire netting is also used into poultry netting for breeding chickens and other poultry. When coated in green, it is commonly used as fencing. Made from galvanized iron wire, hexagonal wire netting is widely used in fences, breeding, and construction reinforcement.

According to the application, we can supply wire netting in the following types:

Gabions Wire Mesh;

Garden Netting;

Poultry Netting, Rabbits and Pet enclosures;

Chicken Wire;

Wire Netting for Fences;

Plastering and reinforcing.

Processing Types available include:

• straight twist hexagonal wire netting

• reverse twist hexagonal wire netting

• double-direction twisted hexagonal wire netting

Finishes of Hexagonal Wire Netting can be:

• galvanized after weaving,galvanized before weaving

• PVC coated galvanized

• hot-dipped galvanized

• electro galvanized

Galvanized after weaving hexagonal wire netting for gabions and rockfall protection:

Hexagonal wire mesh galvanized after weaving is popularly used for gabion work. This type of hexgaonal mesh twisted is fully coated with zinc, providing superior corrosion resistance and durability.

Hexagonal wire mesh is fabricated into gabion baskets by cutting, bending, and forming the wire mesh into the desired gabion shape, then assembling and reinforcingwith lacing wire or C-rings.

Mesh |

Wire dia |

Mesh Width |

|

|

BWG |

mm |

Meter |

3/8" |

27-23 |

0.41-0.64 |

width limit:2M,single or double edge |

1/2" |

27-22 |

0.41-0.71 |

width limit:2M,single or double edge |

5/8" |

27-22 |

0.41-0.71 |

width limit:1.22M,single or double edge |

3/4" |

26-20 |

0.46-0.89 |

width limit:2M,single or double or strong edge |

1" |

25-19 |

0.51-1.07 |

width limit:2M,straight or reversed twist |

1-1/4" |

24-18 |

0.56-1.24 |

width limit:2M,straight or reversed twist |

1-1/2" |

23-16 |

0.64-1.65 |

width limit:2M |

2" |

22-14 |

0.71-2.11 |

width limit:2M |

3" |

21-15 |

0.81-2.11 |

width limit:2M |