Gabions Products

- Military Gabions

- Hot Dipped Galvanized Gabion Mesh Cells

- Welded Mesh Gabions Architectural Wall Cladding

- Gabions (Gabiony)

- Galfan + PVC Coated Gabions

- Gabion Mattresses for Flood Protection Embankment

- Planted Gabion Walls

- Gabions and Geotextiles for Bridge Construction

- Gabion Basket Hot Dip Galvanized

- Gabions P. V. C. Coated Galvanised Wire Box

- Gabions River Training Works

- Geotextile Fabric

- Woven Wire Mesh Cages for Gabion Project

- Gabion Fence

- Welded Gabions Coating Galfan

- Gabion Baskets Double Twisted Galvanized

- Triple Twisted Wire Mesh Gabions

- Gabion Box

- Woven Gabions

- Gabion Baskets

- Wire Mesh Gabion Mattress

- Gabion Cages (Stone Box)

- Gabion Wall

- Hexagonal Gabions Netting

- Gabions Machine

- Welded Gabions

- Sack Gabions

- Reinforced Gabions

- Gabion faced reinforced soil walls

- Gabion Mattress

- Gabions for Water Conservancy

- Gabions for Bridge Protection System

- Gabion Wall Drop Structures

- Modular Gabions as Architectural Elements

- Gravity Wall of Gabions

- Gabions for Headwalls or Wingwalls

- Channel Linings

- Modular Gabions for Rockfall Netting System

Hexagonal Triple Twisted Wire Mesh Gabions PVC Coated Galvanized for Channel Protection Permanent Gabion Works

We supply PVC coated galvanized gabions made of hexagonal triple twisted wire mesh for European customers, supplied with geotextile fabric and binding wire.

Gabion baskets fabricated from triple twisted wire mesh offer enhanced strength and flexibility compared to double twisted mesh gabions. Triple twisted mesh gabions are popularly used in erosion control, retaining structures and flood protection projects.

Gabions of Triple Twisted Hexagonal Mesh

Types:

Gabion basket

Gabion mattress

Gabions 2 X 1 X1, mesh 8X10 hexagonal triple twisted wire mesh complying with BS1485, galvanized to meet BS 443, wire diameter 3.00mm.

Gabion Mattresses: 3X2X0.30 reno mattresses

Wire Fabric Material:

Triple-twisted hexagonal woven steel wire mesh complying with BS 1485.

Wire galvanized before weaving and test samples meet BS 443.

Wire diameter: 3.0mm

Mesh size: 80 x 100 mm

Finish:

PVC coating is applied for the mesh wire, standard tie wires, standard binders, internal connecting wires, preformed stiffeners, and selvage wire. Minimum thickness of the PVC coating must be 0.35mm.

PVC coating is UV resistant

Color: Gray, green and etc.

All gabions mesh materials are supplied with no nicks, cuts, or abradedareas. Minor cuts, nicks, and other minor imperfections due to manufacturing are allowed along the selvage-wrapped edges of the twisted wire mesh.

Tolerances for Gabions and Gabion Wire

Gabion and gabion materials are manufactured to the following tolerances:

Gabion Dimensions:

at a tolerance of + 10% on the width and height of the gabion and a tolerance of - 10% on the length.

Mesh Dimensions: at a tolerance of - 15% on the nominal size of the mesh.

Wire Thicknesses: at a tolerance on the diameter of all wire of - 2.5% in accordance with BS 1052.

Weight of gabions supplied at a tolerance of - 5%.

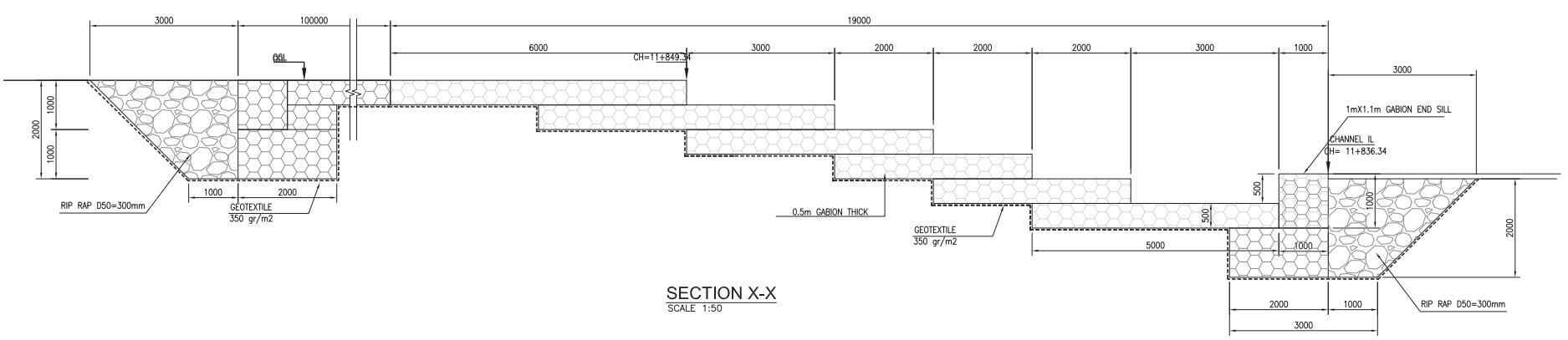

Channel Protection Project- Gabions of Triple Twisted Wire Mesh, Geotextile, Lacing Wire, Assembly

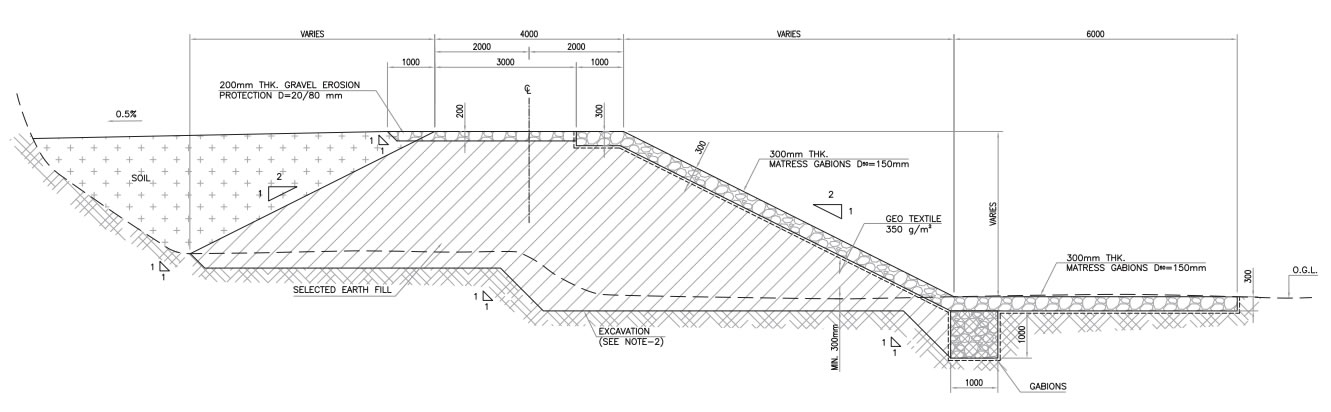

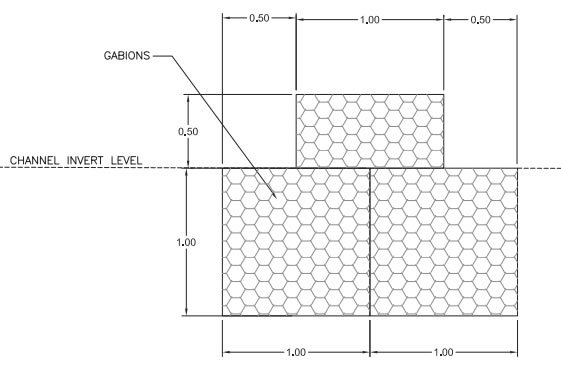

Cross Section of Channel Construction Gabion Works

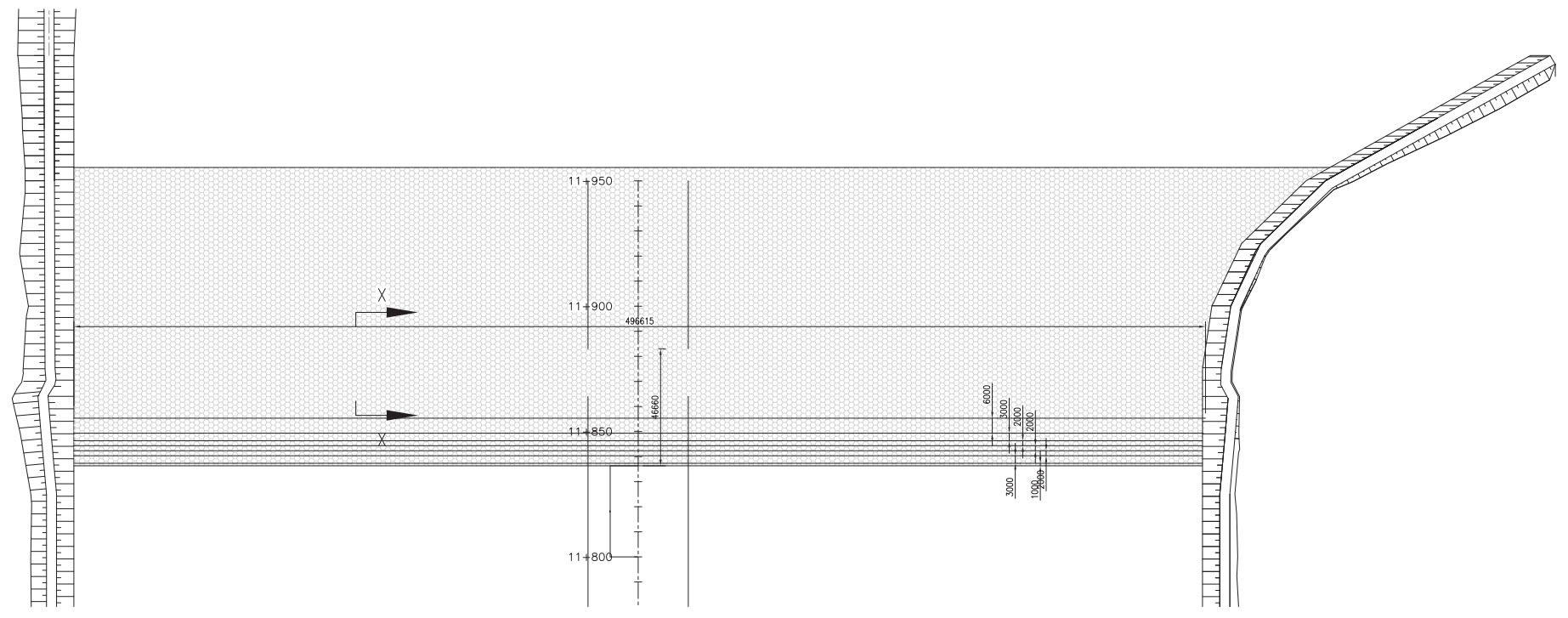

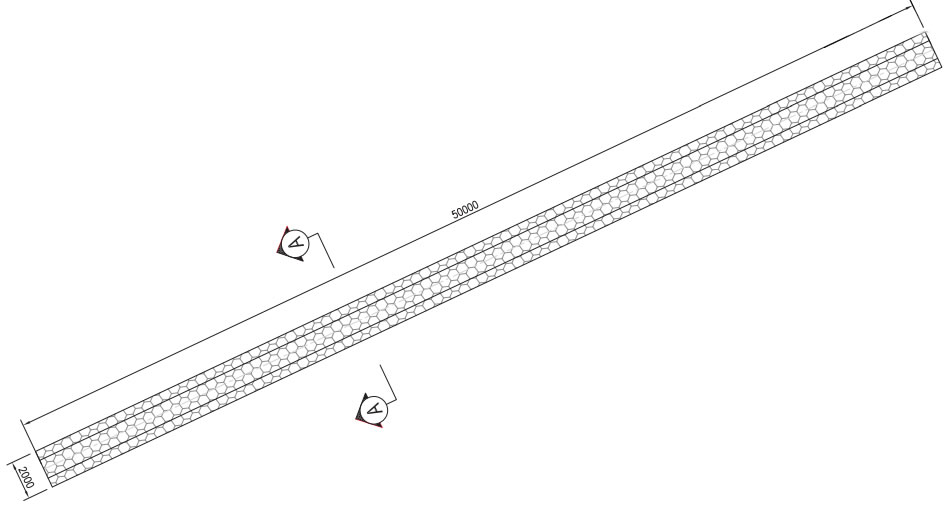

Channel Inlet Plan

Channel Inlet Plan

Channel Inlet Permanent Gabions Work Construction

Geotextile 350gr / m2

Rip rap D50=300mm

Gabion thick: 0.5m

Gabion end sill: 1x1.5m

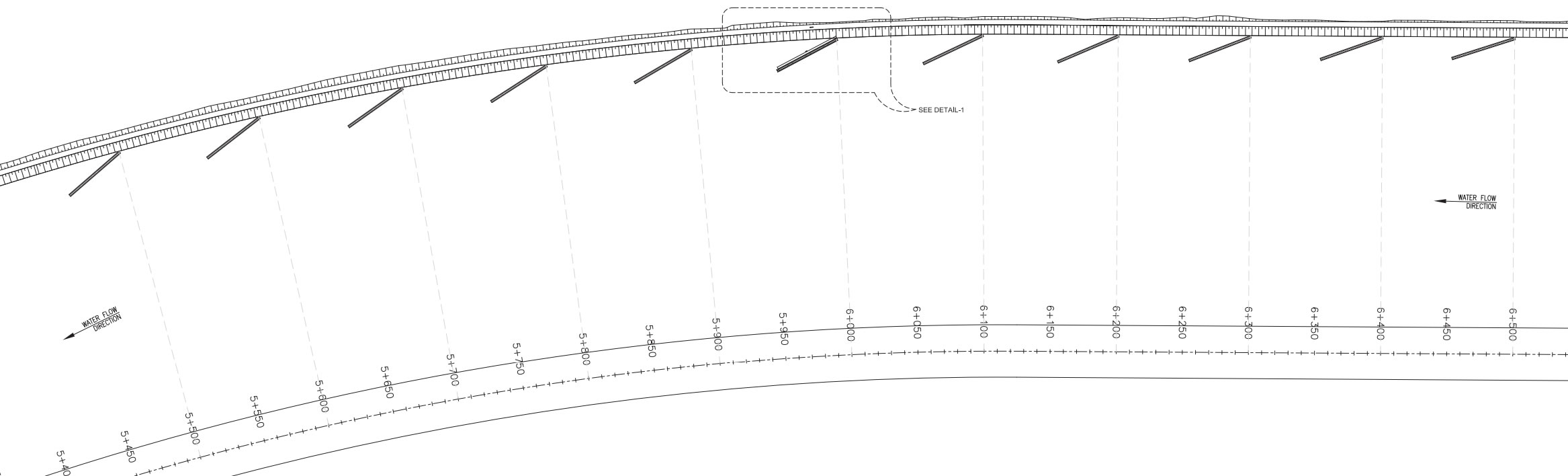

Gabion Protection Plan with Water Flow Direction

Gabion Protection Plan with Water Flow Direction

Gabions for Dike Protection

Box and mattress gabions for Channel Protection

Gabions Technical Specifications

Material:

Zinc coated galvanised gabions fabricated of triple twisted hexagonal wire mesh pvc coated galvanised.

Mattresses and drainage geotextile for mattress gabions.

Gabion mattresses galvanised fabricated from wire mesh and selvedge wire. Each mattress is divided by diaphragms into cells, the cell length is no greater than the width of the gabions or mattresses plus 100 mm.

Gabion mattresses are supplied with galvanised wire for fastening and wiring of the gabions and mattresses on site.

Wire material for gabions and mattresses is galvanised similar to or stronger than that used in galvanised gabions.

The wires in the gabions and mattresses are arranged into spacing between the wires per the international standards.

Geotextile:

Properties:

Nominal weight (g/m2) :350

Water flow (l/m2/s) at 100 mm head: 35

Geotextile Fabric Laying and Storage

When laying the geotextile fabric, ensure that there is a minimum overlap of 1.0 meter at the edges and ends.

Geotextile fabric rolls shall be stored from water and direct sunlight.

Installation and Maintenance

Place the backfill material carefully to prevent any damage or movement of the geo fabric, ensuring that the foundation remains protected. Cover the geotextile within 24 hours of unrolling to limit exposure to sunlight.

Additionally, no vehicular traffic is permitted on the fabric after installation to avoid any potential damage.

Binding Wire and Lacing Wire

We supply with gabions binding wires and lacing wire for the wiring in the construction of the gabion work.

Binding wire material:

Box gabions and mattresses selvedge wire diameter: 3.90 mm min., galvanised and PVC coated.

Lacing wire diameter: 2 40 mm, galvanised and PVC coated.

Gabions Assembly

We provide instructions on gabions and mattresses assembling and filling.

This guide covers the preparation, positioning, filling, and final adjustments needed for proper gabion installation.

Preparing Gabion Mattresses

Gabion mattresses are placed on the spillway section of embankments, aligned with the long dimension down slope, with a maximum compartment dimension of 1.0m. When two layers are present, the upper layer should be laid directly on the lower layer, with all adjacent selvedge wires laced. The gabions should be unpacked, unfolded on a hard flat surface, stretched out, and stamped to remove unnecessary creases. Raise the sides and internal diaphragms to the vertical position, ensuring they are of equal height. Secure the diaphragms upright to the sides using helical wire to connect each diaphragm to the bottom of the gabion.

Assembling and Lacing Gabions

Each contact point between gabion baskets, diaphragms, and lids should be laced. Use individual lacing wire of at least 2,000mm in length, joining wires as necessary. Lacing should be done continuously, with the wire passing through every mesh with double turns. All lacing connections consist of five close turns by pliers. The assembled gabions are carried to final position, securely wired to adjoining gabions to form continuous joints along adjacent edges, including the bottom edges, and placed empty.

Positioning and Filling Gabions

Gabion units are placed on headers and stretchers in alternate courses, with staggered vertical joints. Gabions may be filled with stones tightly packed to minimize voids, ensuring the void size does not exceed the minimum particle size specified and the voids ratio is less than 30%. For gabions on slopes, filling should start at the bottom. Avoid using flat stones for possible bulging. In basket gabions with exposed faces, fix bracing wires laterally and vertically, ensuring even tension to avoid bulges.

Gabion Rock Specifications

Stones for gabions must be clean, natural, hard, and durable. Stones are generally well-graded boulders between 60mm and 250mm. Rocks for gabion baskets 600mm or higher should comply with specified gradations. The unit weight of a rock-filled gabion must be at least 18 kN/m³.

Gabions Final Adjustment

Gabions should be overfilled by 50 mm to allow for settlement. Stretch the gabion lids tightly over the fill material and secure them to the edges and diaphragms. Fill any voids between the fill and lid with small stones, ensuring no small stones appear on exposed faces.

For non-standard structures, cut, fold, and wire gabion mesh to form mitre joints, angles, curves, or slopes, ensuring clean cuts and secure lacing.

Completed gabion structures are straight and vertical, with a maximum allowable departure from vertical of 50 mm.